Submerged ultrafiltration is a submerged ultrafiltration system developed based on ultrafiltration membrane modules. SMF is an improved process of MBR (membrane bioreactor). It uses membrane modules to replace the secondary settling tank in the traditional process for solid phase and liquid phase separation.

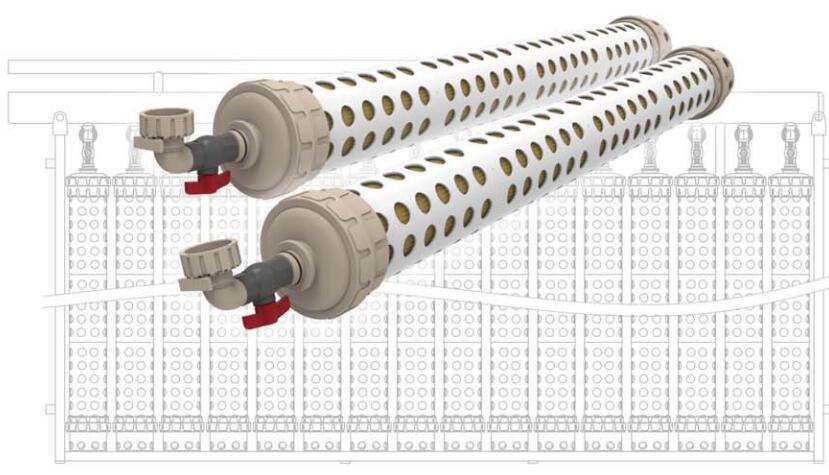

The Specification table of the SF-635 and ST-635:

| Membrane module type | SF-635 | ST-635 | |

| Membrane module parameters | Membrane manufacture method | NIPS | C-TIPS |

| Effective membrane area( m2 ) | 35 | ||

| Maximum pore size ( um ) | 0.03 | ||

| Membrane module size | LengthxOutside diameter (mm) | 1800*160 | |

| Connection size | Joint connection(DN) | 32 | |

| Connection mode (Locknut) | M65*3 | ||

| Membrane module weight | Moist weight(kg) | 16 | |

| Operation condition | Filtration type | Dead-end filtration | |

| Maximum TMP(kPa) | 50 | 80 | |

| Temperature range (C ) | 1-40 | ||

| Using pH range | 6--8 | ||

| Tolerate pH range | 1--10 | ||

| 20C designed flux ( L/m2.h ) | 35--43 | ||

| Air flux during air backwash ( Nm3/h ) | 3--5 | 10 | |

| Water fux during backwash ( m2/h) | 1.8--2.0 | ||

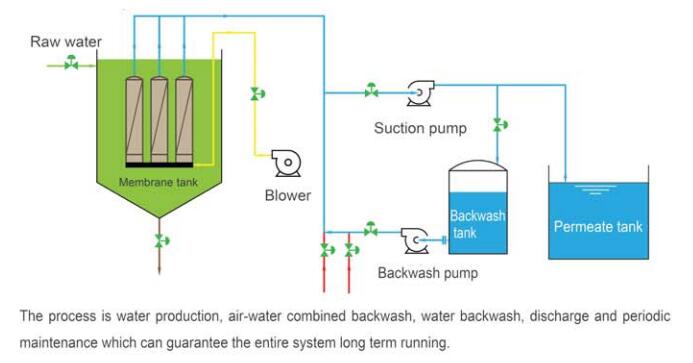

The flow chart of column hollow fiber ultrafiltration membrane modules SF-635 :

Advantage:

a) Wide range of use and easy to clean. The membrane material of SMF series products is PVDF (polyvinylidene fluoride) material, which has strong chemical resistance and has a wide range of applications. The components can be cleaned online or offline in time when filtering.b) Low energy consumption and high efficiency. It contains 10m2 hollow fiber membranes in a space of about 0.02m3. The membrane module is immersed in water and can maintain a high flux at a low pressure of 0.05 MPa, so the energy consumption is very low.

c) High filtration precision and continuous filament. The hollow fiber used has uniform pores less than 0.05μm, which can remove microorganisms, colloids, algae and other substances that cause turbidity. And due to the TiO2 hybridization, the tensile properties of the membrane filaments are far stronger than ordinary PVDF membranes.

d) High flux and high anti-fouling ability. Due to the addition of nanoparticles, the membrane module greatly improves the hydrophilicity of the membrane surface, and significantly improves the membrane flux and anti-fouling performance.

e) Good effect of nitrogen and phosphorus removal. The hydraulic retention time (HRT) and the sludge retention time (SRT) are completely separated, so that the nitrifying bacteria can survive in the reactor and ensure good nitrification.

f) Small footprint. There is no need to set up solid-liquid separation equipment such as precipitation and filtration, which makes the whole system process simple and easy to integrate, and the system area is greatly reduced. G) Simple and convenient management, high degree of automation and low operating cost. No need to set up disinfection equipment, no need to add medicine, no need to control residual chlorine. The whole machine can realize automatic intermittent operation.

h) SMF membrane stack frame is made of stainless steel, any membrane can be freely disassembled and assembled, and the membrane group adopts a standard modular design.