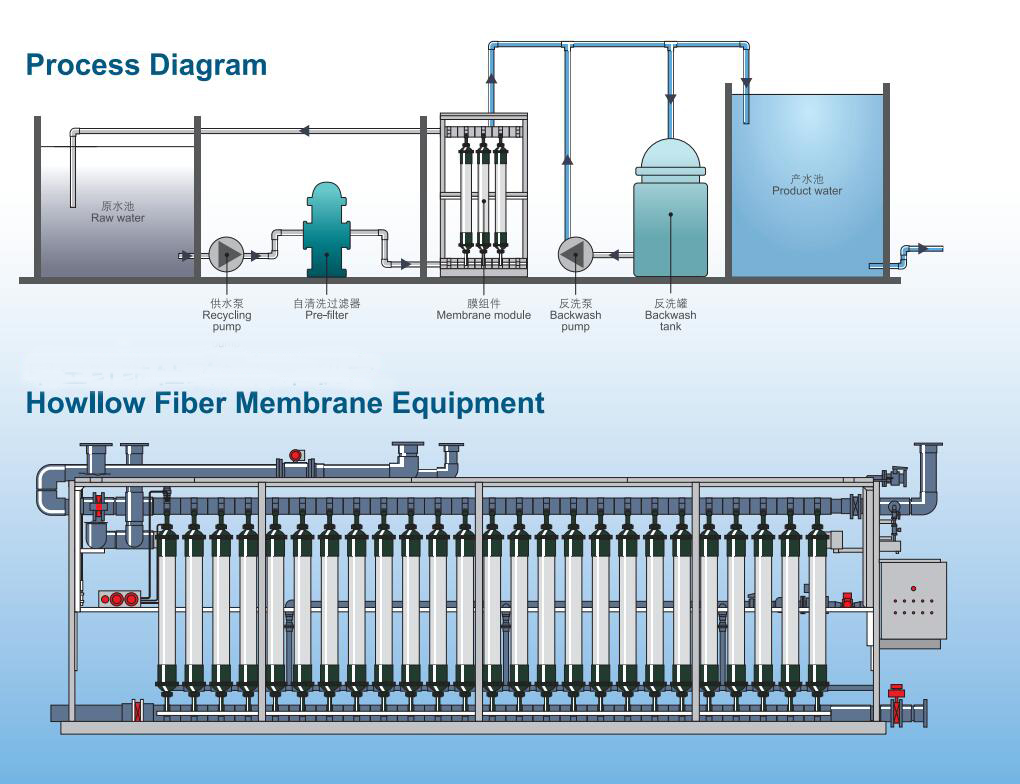

Continuous Membrane Filtration (CMF) refers to a membrane filtration unit specially used for water treatment and reuse, reverse osmosis and nanofiltration pretreatment projects, and the treatment of materials with relatively high turbidity.

The CMF system adopts a highly anti-pollution hollow fiber membrane element with a unique structure and a unique air-water double washing process technology, and is equipped with specially designed pipeline valves, self-cleaning units, dosing units and automatic control units, etc., forming a closed circuit Continuous operating system. The CMF system is particularly suitable for filtering tap water, groundwater, surface water and municipal sewage after biochemical treatment to remove impurities such as bacteria, microorganisms and suspended solids. The purified water is clear and transparent, and the turbidity is close to zero.

The Principle

MF column type membrane filtration is a pressure actuation membrane separation process, it can separate the particulate matter from the liquid of the dissolved component. Highly efficient removal of Colloid, silt, algae,Cryptosporidium, Giardiasis Tyzzer, coliform, bacterium and majority virus, the elimination rate is 4~6 lg.

The Specification table of the UOT 640 :

Type |

UOT 640H |

UOT 640G |

Pure water flux (25 C, 0.1 MPa) |

7000--8000 L/h |

6000--7000 L/h |

Permeate turbidity |

≤0.2 NTU |

|

SS |

≤1 mg/L |

|

Membrane filtration style |

Outside-in hollow fiber membrane |

|

Material |

PVDF |

|

Hollow fiber inside diameter |

0.7mm |

0.6mm |

Holow fiber outside diameter |

1.2mm |

1.1mm |

Adhesive material |

Epoxy resin |

|

Shell material |

UPVC |

|

Membrane area |

40m2 |

|

Pore size |

0.1um |

0.03um |

The operational parameters of column hollow fiber ultrafiltration membrane modules UOT 640 :

Type |

UOT 640H |

UOT 640G |

Designed water flux for secondary sedimentation tank (20°C, 0.1 Mpa) |

1800--2500L/h |

1500--2500L/h |

Maximum water supply pressure |

0.2 Mpa |

|

Maximum supply water flux |

6000 L/h |

|

Trans membrane pressure |

0.15 Mpa |

|

Temperature range |

1~40 ℃ |

|

Acidity and alkalinity range |

pH2~ 10 |

|

Operation type |

Volume fltration or Cos-flow fltration |

|

Maximum backwash water quantity |

3000 L/h/module |

|

Air consumption |

2.5~ 5 m3/h/module |

|

Backwash time |

20~ 60s |

|

Backwash pressure |

0.03 ~ 0.05 Mpa |

|

Backwash water fux / air+water |

0.3 ~ 1.0 m3 /h/module |

|

Backwash water fux/ only water |

2~ 3.0 m3/h/module |

|

Backwash time |

20~ 60s |

|

Perneate fux |

2000L/h |

|

Operating pressure |

0.03 ~ 0.06Mpa |

|

Chemical cleaning period |

4~ 24 weeks |

|

In-line water wash period |

50~ 90s/ 20~ 60 min |

|

Advantage:

1. The material is PVDF ,High chemical stability2. High acid and alkali resistant and strong oxidation resistance

3. Membrane noodle is fingered hole-anisomerous structure, high ant-pollution, not easy to in-depth pollution

4. High water flux in each membrane unit, Ultra-low presure cost, long service life

5. Outside-in filter type: saving cleaning water, low operating costs

6. Excellent quality, reached advanced international standards, is highly cost-effective