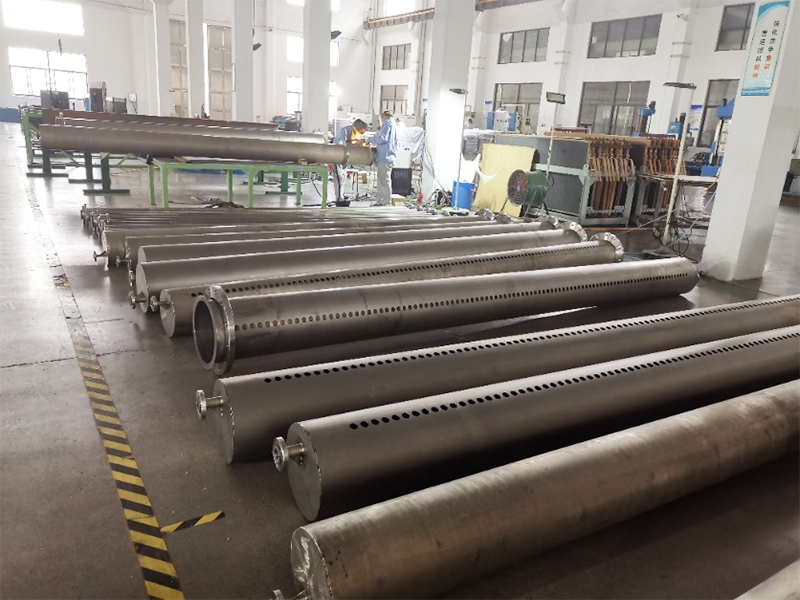

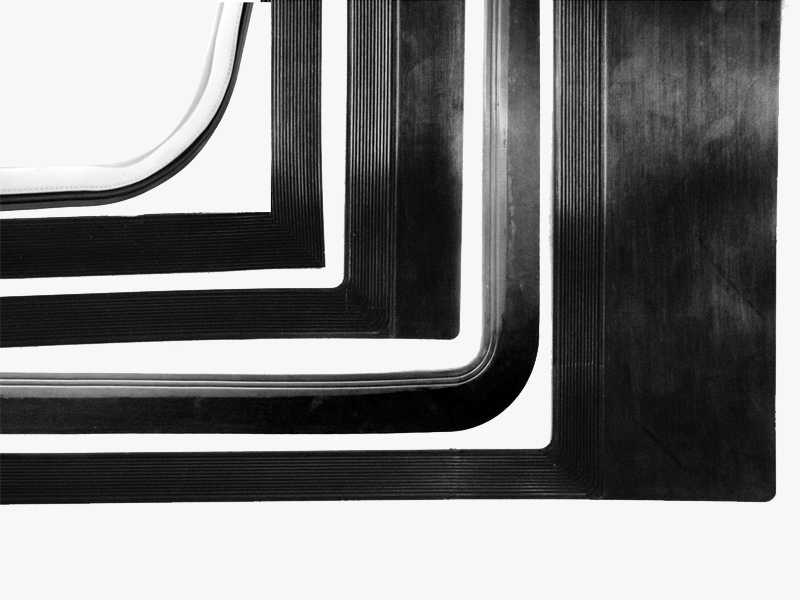

The supply of high-quality accessories is essential to improve the entire repair results. At present, the various models of ion-exchange membrane unit cell accessories produced by our company are sufficient to meet the regular replacement needs of customers, and our company is still expanding its scope of supply.

Operating Instructions:

1, the voltage: <2.8—3.0v2, the current density: 3.0—6.0 kA/m2

3, or based on the operation condition

Quality of feeding brine:

No. |

Item |

Specifications |

1 |

NaCl |

300--320 g/l |

2 |

Ca+Mg |

<0.02 mg/l |

3 |

Sr |

<0.05 mg/l |

4 |

Ba |

<0.5 mg/l |

5 |

SiO2 |

<2.3 mg/l |

6 |

Al |

<0.1 mg/l |

7 |

I |

<0.2 mg/l |

8 |

Fe |

<0.1 mg/l |

9 |

Ni |

<0.01 mg/l |

10 |

ClO3 |

<15 mg/l |

11 |

SO4 |

<7 g/l |

12 |

TOC |

<10 mg/l |

13 |

SS |

<1 mg/l |

14 |

PH |

9--10 |

Applications:

Our Chlor-alkali electrolyzer is suitable for 30-32% caustic soda production.Our Chlor-alkali electrolyzer is suitable for the production of Sodium hypochlorite

The advantage of our Chlor-alkali electrolyzer:

1. A finer anode net can reduce the voltage of the cell and reduce the gas staying on the surface of the anode net2. The innovative V-shaped corrugated diversion structure can use the electrolyte gas lift function to make the electrolyte inside the electrolytic cell mix more evenly

3. Superior defoaming structure of gas-liquid separation box, complete foam breaking and small outlet pressure fluctuation

4. The superior spring structure on the cathode side has more than 30,000 contact points, which can make the current density distribution of the cathode network more uniform and reduce the voltage

5. Capable of resisting directional current

6. Different models of electric tanks can be produced according to customer needs